This manual provides essential guidance for operators and technicians, detailing systematic approaches to identify and resolve issues with the Skyjack 3219 scissor lift, ensuring optimal performance.

1.1 Overview of the Skyjack 3219 Scissor Lift

The Skyjack 3219 is a DC electric scissor lift designed for versatility and reliability, ideal for indoor and outdoor applications. Known for its compact design and maneuverability, this model is widely used in construction, maintenance, and industrial settings. With a weight capacity of 500 lbs and a maximum lift height of 19 feet, the Skyjack 3219 offers efficient performance for elevated work tasks. Its battery-powered operation ensures quiet functioning and reduced emissions, making it suitable for environmentally sensitive environments. The lift features a robust construction, intuitive controls, and advanced safety mechanisms, ensuring operator confidence and productivity. Understanding its design and capabilities is essential for effective troubleshooting and maintenance, as outlined in this manual.

1.2 Importance of Regular Troubleshooting

Regular troubleshooting is crucial for maintaining the Skyjack 3219’s performance and longevity. It helps identify and address issues before they escalate, minimizing downtime and ensuring operational efficiency. By adhering to the manual’s guidelines, operators can quickly resolve problems, reducing the risk of costly repairs and enhancing workplace safety. Early detection of malfunctions also prevents potential accidents, ensuring a safer environment for workers. Additionally, consistent troubleshooting supports compliance with industry standards and extends the lifespan of the equipment. This proactive approach not only safeguards the machine but also upholds productivity, making it an essential practice for all Skyjack 3219 users.

Key Features of the Skyjack 3219

The Skyjack 3219 is a DC electric scissor lift featuring a compact design, load-sensing systems, and advanced safety alarms for efficient and secure operation in various environments.

2.1 Design and Specifications

The Skyjack 3219 is a DC electric scissor lift designed for versatility and performance. It features a compact design, making it ideal for indoor and tight-space applications. With a maximum platform height of 19 feet and a lift capacity of 500 lbs, it efficiently handles various tasks. The lift is equipped with a load-sensing system, which ensures safe and stable operation by preventing overload. Its durable steel construction enhances longevity, while the zero-emission electric motor provides eco-friendly operation. The platform measures 5′ 11″ x 2′ 6″, offering ample workspace. Designed for ease of use, the Skyjack 3219 includes intuitive controls and a robust hydraulic system. Its low noise levels and efficient battery performance make it suitable for noise-sensitive environments. This model is built to deliver reliable performance across industrial and construction settings.

2.2 Safety Mechanisms and Alarms

The Skyjack 3219 incorporates advanced safety mechanisms to protect operators and bystanders. Key features include overload protection, which prevents operation when the lift exceeds its rated capacity. The load-sensing system alerts users if weight limits are surpassed, ensuring stability. An emergency stop button is conveniently located for quick shutdown in critical situations. Additionally, the lift is equipped with alarm systems that trigger during platform overload or unauthorized access. These alarms are audible and visual, providing clear warnings. The scissor lift also features a robust braking system and automatic leveling for secure positioning. These safety mechanisms work in tandem to minimize risks and ensure safe operation across various work environments, aligning with industry safety standards and regulations.

Common Issues and Their Solutions

Common problems with the Skyjack 3219 include hydraulic system leaks, electrical malfunctions, and control system errors. These issues often result from wear, improper maintenance, or component failure.

3.1 Hydraulic System Problems

The Skyjack 3219 may experience hydraulic system issues such as fluid leaks, pump failure, or cylinder malfunctions. These problems often arise due to wear and tear, contamination, or improper maintenance. Operators should inspect hydraulic lines and connections regularly for signs of damage or leaks. If a leak is detected, it is crucial to replace the faulty seals or hoses immediately to prevent further damage. Additionally, ensuring the hydraulic fluid is clean and at the recommended level can prevent system failures. In cases of pump failure, refer to the service manual for replacement procedures. Addressing these issues promptly helps maintain the lift’s performance and safety.

3.2 Electrical System Issues

The Skyjack 3219 may encounter electrical system problems, such as malfunctioning sensors, wiring issues, or battery-related faults. Common symptoms include error codes on the control panel or unexpected shutdowns. To troubleshoot, inspect sensors and wiring for damage or corrosion, and ensure all connections are secure. Battery issues can often be resolved by checking charge levels and ensuring proper connections. If problems persist, consult the service manual for diagnostic procedures. Addressing electrical issues promptly prevents further complications and ensures reliable operation.

3.3 Control System Malfunctions

Control system malfunctions in the Skyjack 3219 can result in erratic or unresponsive operation. Common issues include faulty joystick or button controls, incorrect limit switch settings, or miscommunication between sensors and the control module. To diagnose, inspect the control panel for error codes and verify all wirings and connectors for damage or corrosion. Test the joystick and buttons to ensure proper functionality. Check the manually operated valves, as they can often be overlooked and may cause operational disruptions. Refer to the service manual for advanced diagnostic procedures, such as recalibrating sensors or resetting the control system. Addressing these issues promptly ensures smooth and safe operation of the scissor lift.

Regular Maintenance and Inspection

Regular maintenance ensures the Skyjack 3219 operates safely and efficiently. Follow the service manual for scheduled checks, including hydraulic fluid levels and control system functionality.

4.1 Pre-Operational Checks

Before operating the Skyjack 3219, perform a thorough pre-operational inspection to ensure safety and functionality. Start by checking the hydraulic fluid levels and top them off if necessary. Inspect the electrical connections and control systems for any damage or wear. Test all safety mechanisms, including alarms and emergency stop buttons, to confirm they are functioning correctly. Verify the condition of tires or wheels and ensure proper inflation. Conduct a visual inspection of the lift structure for any signs of damage or corrosion. Finally, test the lift and drive functions to ensure smooth operation. Address any issues immediately to prevent accidents and downtime. Regular pre-operational checks are crucial for maintaining equipment reliability and operator safety.

4.2 Scheduled Maintenance Procedures

Regular maintenance is critical to ensure the Skyjack 3219 operates efficiently and safely. Schedule periodic inspections and servicing as outlined in the manual. Replace hydraulic fluid and filters every 500 hours or as recommended. Inspect and clean electrical connections to prevent malfunctions. Lubricate moving parts and check for wear on components like hydraulic hoses and belts. Inspect tires or wheels for damage and ensure proper inflation. Test safety mechanisms, such as alarms and emergency stops, to ensure they function correctly. Follow the manufacturer’s maintenance schedule to avoid unexpected downtime. Keep a record of all maintenance activities for future reference and warranty purposes. Regular servicing not only extends the equipment’s lifespan but also enhances workplace safety and productivity.

Advanced Troubleshooting Techniques

Advanced techniques involve using diagnostic tools to identify root causes of complex issues, ensuring efficient problem resolution and minimizing downtime for the Skyjack 3219.

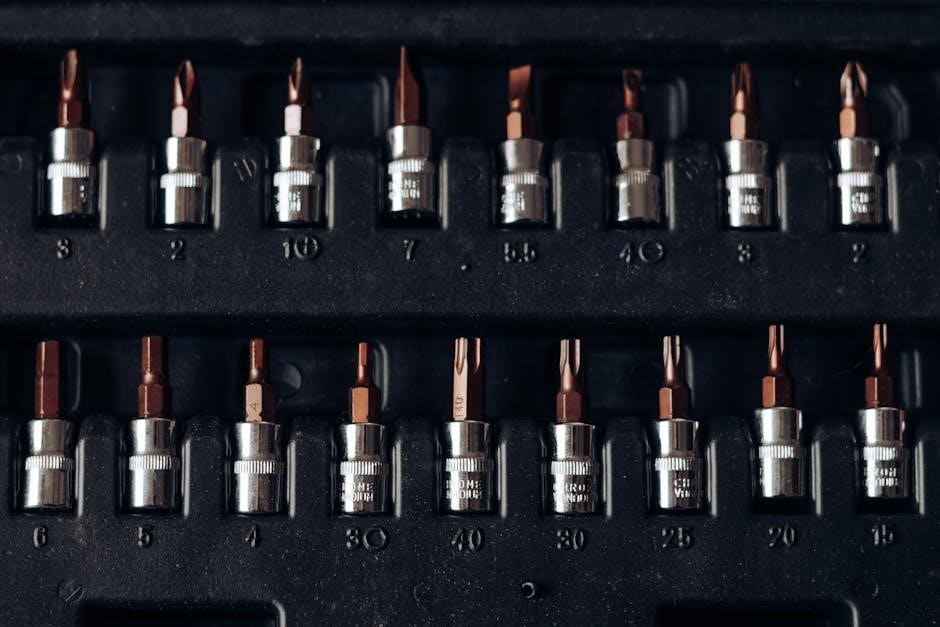

5.1 Using Diagnostic Tools

Diagnostic tools are crucial for identifying complex issues in the Skyjack 3219. These tools, such as error code scanners and multimeters, help pinpoint faults in hydraulic, electrical, and control systems. By connecting to the lift’s onboard computer, technicians can retrieve error codes and analyze real-time data. Advanced software provided by Skyjack allows for detailed system monitoring, enabling precise troubleshooting. Regular use of these tools ensures quick resolution of problems, minimizing downtime and extending equipment lifespan. Proper training is essential for effective utilization of diagnostic equipment, ensuring accurate diagnoses and efficient repairs. Integrating these tools into maintenance routines enhances overall operational efficiency and reliability of the Skyjack 3219.

5.2 Solving Complex Mechanical Issues

Tackling complex mechanical issues in the Skyjack 3219 requires a systematic approach. Start with a thorough inspection of hydraulic lines, cylinders, and valves, as these are common sources of mechanical failure. Refer to the service manual for detailed procedures and torque specifications. For issues like pump failures or motor malfunctions, use diagnostic tools to identify fault codes and trace the root cause. In cases involving electrical-hydraulic integration, consult the troubleshooting guide for specific reset procedures. Complex problems may require advanced techniques, such as disassembling components or replacing seals and bearings. Always follow safety protocols and use specialized tools to avoid further damage. For severe issues, contact Skyjack’s technical support or authorized service centers for professional assistance. Regular maintenance can prevent many of these complex mechanical problems from arising.