The Vici Vision M1218 Techno manual is a comprehensive guide for operating and maintaining the machine, available as a downloadable PDF for easy access and reference.

1.1 Overview of the Vici Vision M1218

The Vici Vision M1218 is a high-precision optical measuring machine designed for cylindrical parts, offering a measuring field of 1250mm in length and 180mm in diameter. With a load capacity of 60kg, it ensures accurate measurements for production needs. Its modular design enhances versatility, making it suitable for various industrial applications. Built for reliability, the M1218 is part of the Techno series, known for advanced optical technology and user-friendly operation, catering to diverse production environments with efficiency and precision.

1.2 Importance of the Manual for Optimal Machine Operation

The Vici Vision M1218 Techno manual is essential for optimal machine operation, offering detailed guidance on operation, maintenance, and troubleshooting. It empowers users to unlock the machine’s full potential, understand its advanced features, and efficiently address common issues. The manual includes valuable calibration tips and maintenance schedules, which are crucial for maintaining precision and extending the machine’s operational lifespan. Easily accessible as a PDF, it serves as a vital resource for maximizing efficiency, ensuring reliable performance, and supporting high-quality production environments.

Key Features of the Vici Vision M1218

The Vici Vision M1218 features high-resolution optical measurement technology, a 1250×180 mm measuring field, and a 60kg load capacity, ensuring precision and versatility in production environments.

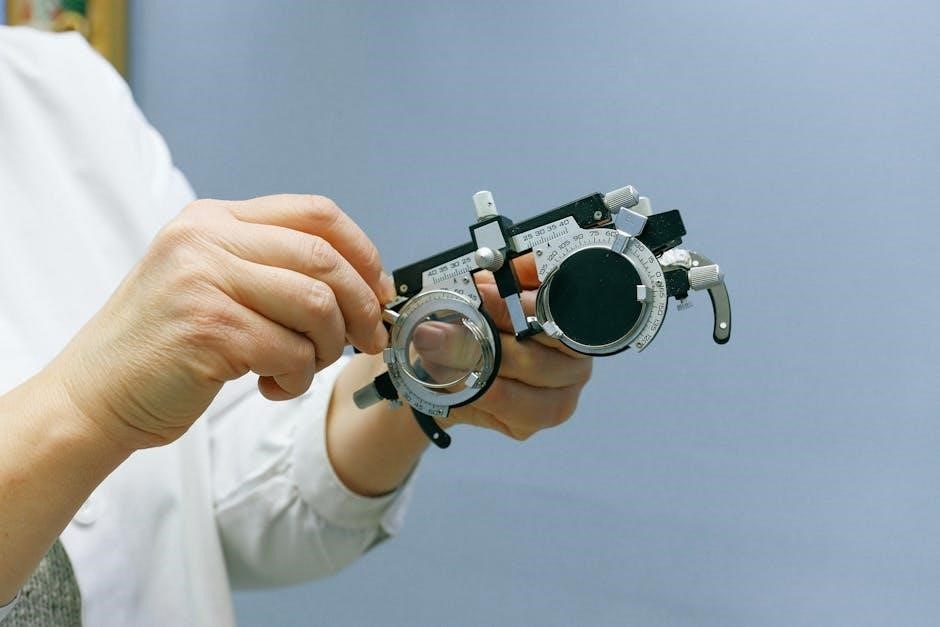

2.1 High-Resolution Optical Measurement Technology

The Vici Vision M1218 utilizes advanced high-resolution optical measurement technology to capture precise details of cylindrical parts. This system ensures accurate measurements, essential for quality control in production. The optical technology is complemented by a touch probe system, enhancing its versatility for complex geometries. With its ability to handle parts ranging from 40 to 180 mm in diameter and 300 to 1250 mm in length, the M1218 delivers exceptional precision and reliability. This feature makes it a cornerstone of the Techno series, trusted for industrial applications requiring utmost accuracy and efficiency. The manual provides detailed guidance on optimizing this technology for consistent results.

2.2 Measuring Field and Load Capacity Specifications

The Vici Vision M1218 offers a measuring field of 1250 mm in length and 90 to 180 mm in diameter, catering to a wide range of cylindrical parts. Its load capacity is 60 kg, ensuring robust performance for demanding applications. These specifications make it ideal for precise measurements in industrial environments, aligning with the needs of modern production lines. The manual details how to utilize these capabilities effectively, ensuring optimal performance and accuracy in various operational settings.

2.3 Modular Design for Versatility in Production

The Vici Vision M1218 features a modular design, allowing seamless integration into diverse production environments. This adaptability ensures the machine can be tailored to specific manufacturing needs, enhancing efficiency and workflow. The modular system supports various configurations, making it suitable for a range of applications. The manual highlights how this design enables easy customization and scalability, ensuring the M1218 remains a versatile tool in modern production settings.

Where to Download the Vici Vision M1218 Techno Manual PDF for Free

The Vici Vision M1218 Techno manual can be downloaded for free from the official Vici Vision website or trusted third-party sites, ensuring easy access to comprehensive guidance.

3.1 Official Sources for the Manual

The official Vici Vision website (www.vicivision.com) provides direct access to the M1218 Techno manual PDF for free. This ensures authenticity and reliability. Users can download the manual, user guides, and troubleshooting documents effortlessly. The official source guarantees comprehensive and up-to-date information, essential for optimal machine operation. Additionally, Vici Vision’s customer support can be contacted via phone or email for assistance. This direct access eliminates the risk of downloading outdated or incorrect versions, ensuring users have the most accurate guide for their needs.

3.2 Trusted Third-Party Websites for Download

Besides the official website, trusted third-party platforms offer the Vici Vision M1218 Techno manual PDF for free. These include reputable repositories like ManualsLib and ManualsOnline, which host a wide range of user manuals. Additionally, academic and industrial forums may share the manual, ensuring accessibility. These sources are verified for reliability and safety, providing users with alternative download options if the official site is inaccessible. Always verify the source’s credibility to avoid downloading incorrect or outdated versions of the manual.

How to Use the Vici Vision M1218 Techno Manual Effectively

Navigate the manual quickly for easy reference, understand technical specifications, and use diagrams to optimize machine operation and maintenance, ensuring maximum efficiency and productivity.

4.1 Navigating the Manual for Quick Reference

The Vici Vision M1218 Techno manual is designed for easy navigation, with a clear table of contents and detailed sections. Users can quickly locate information on operation, maintenance, and troubleshooting. The PDF format allows for efficient searching and bookmarking of key pages. Familiarize yourself with the manual’s structure to access technical specifications, diagrams, and guides swiftly. This ensures optimal use of the machine and rapid resolution of operational queries, making it an indispensable resource for both novice and experienced operators.

4.2 Understanding Technical Specifications and Diagrams

The Vici Vision M1218 Techno manual provides detailed technical specifications and diagrams to help users understand the machine’s capabilities. The measuring field of 1250mm in length and 90mm to 180mm in diameter is clearly outlined, along with a load capacity of 60kg. Diagrams illustrate key components, such as the optical measurement system and modular design, ensuring precise operation. These resources enable users to interpret technical data accurately, facilitating efficient setup, measurement, and troubleshooting. Understanding these elements is crucial for maximizing the machine’s performance and ensuring reliable results in production environments.

Technical Specifications of the Vici Vision M1218

The Vici Vision M1218 features a measuring range of 1250mm in length and 90mm to 180mm in diameter, with a load capacity of 60kg and dimensions of 920x1030x2205mm.

5.1 Measuring Range and Accuracy

The Vici Vision M1218 offers a measuring range of 1250mm in length and 90mm to 180mm in diameter, ensuring precise measurements for cylindrical parts. Its high-resolution optical measurement technology delivers exceptional accuracy, making it ideal for industrial applications. The machine’s load capacity of 60kg further enhances its versatility in handling various production requirements. With advanced optical systems, the M1218 provides reliable and consistent results, making it a benchmark for quality control in manufacturing environments.

5.2 Machine Dimensions and Weight

The Vici Vision M1218 measures 920x1030x2205 mm and weighs approximately 920 kg, making it a robust yet manageable machine for industrial settings. Its compact design allows for efficient placement in production areas without compromising performance. The machine’s dimensions ensure stability, while its weight distributes evenly, supporting precise measurements. The M1218’s size and weight are optimized for industrial use, balancing portability with durability to meet the demands of various manufacturing environments.

5.3 Compatibility with Various Production Environments

The Vici Vision M1218 is designed to adapt seamlessly to various production environments, from small-scale workshops to large industrial facilities. Its modular design ensures compatibility with diverse manufacturing setups, allowing it to integrate effortlessly with existing machinery. Whether in high-volume production or precision-oriented environments, the M1218 delivers consistent performance. Its robust construction and versatile functionality make it suitable for a wide range of industrial applications, ensuring reliability and efficiency across different operational demands.

Troubleshooting Common Issues with the Vici Vision M1218

The manual provides detailed solutions for common operational issues, such as calibration errors or sensor malfunctions, ensuring quick resolution and minimal downtime in production environments.

6.1 Diagnosing and Resolving Operational Problems

The Vici Vision M1218 Techno manual offers a systematic approach to diagnosing issues, such as alignment errors or sensor malfunctions. Users can identify problems through error codes and detailed troubleshooting guides. By following step-by-step instructions, operators can resolve common issues like calibration discrepancies or software glitches. The manual also provides tips for preventing recurring problems, ensuring smooth machine operation. Regular maintenance and adherence to diagnostic procedures are emphasized to minimize downtime and optimize productivity in production environments; This section is essential for users seeking to independently address and fix operational challenges efficiently.

6.2 Calibration and Maintenance Tips

Regular calibration is essential for maintaining the Vici Vision M1218’s accuracy. The manual provides detailed steps for recalibrating sensors and aligning optical components. Users are advised to clean the measuring field and optical surfaces frequently to prevent interference. Additionally, routine checks of the machine’s alignment and load capacity ensure optimal performance. Scheduling periodic maintenance, as outlined in the manual, helps prevent unexpected downtime. By following these tips, operators can extend the machine’s lifespan and ensure precise measurements consistently. Proper upkeep is crucial for sustaining the M1218’s high performance standards in industrial settings. Regular maintenance ensures reliability and accuracy.

The Vici Vision M1218 Techno manual is an indispensable resource for optimal machine operation. It ensures precision, efficiency, and longevity, making it a must-have for all users.

7.1 Final Thoughts on the Importance of the Manual

The Vici Vision M1218 Techno manual is a cornerstone for users, providing detailed insights into operation, troubleshooting, and maintenance. It ensures optimal performance and longevity of the machine, making it indispensable for industries relying on precision and efficiency. By following the manual, users can unlock the full potential of the M1218, streamline workflows, and maintain high-quality production standards. Its availability in PDF format ensures easy access, making it a must-have resource for anyone working with this advanced optical measuring technology.

7.2 Encouragement to Utilize the Manual for Maximum Efficiency

Embrace the Vici Vision M1218 Techno manual as a vital tool for maximizing productivity and efficiency. Its detailed guidance ensures optimal machine performance, troubleshooting, and maintenance. By referencing the manual, users can resolve issues quickly, reduce downtime, and maintain high-quality output. The free PDF format makes it easily accessible, serving as a handy future reference. Leveraging this resource empowers users to unlock the full potential of the M1218, ensuring precise measurements and seamless integration into production workflows for years to come.